introduction to high pressure water jets

Introduction to High Pressure Water Jets

High pressure water jets have revolutionized various industries with their ability to cut, clean, and shape materials with precision and efficiency. This technology leverages the power of high-speed water streams, making it a versatile tool in both industrial and commercial settings. In this article, we will explore the fundamental aspects of high pressure water jets, including their applications, benefits, and considerations for use.

The Science Behind High Pressure Water Jets

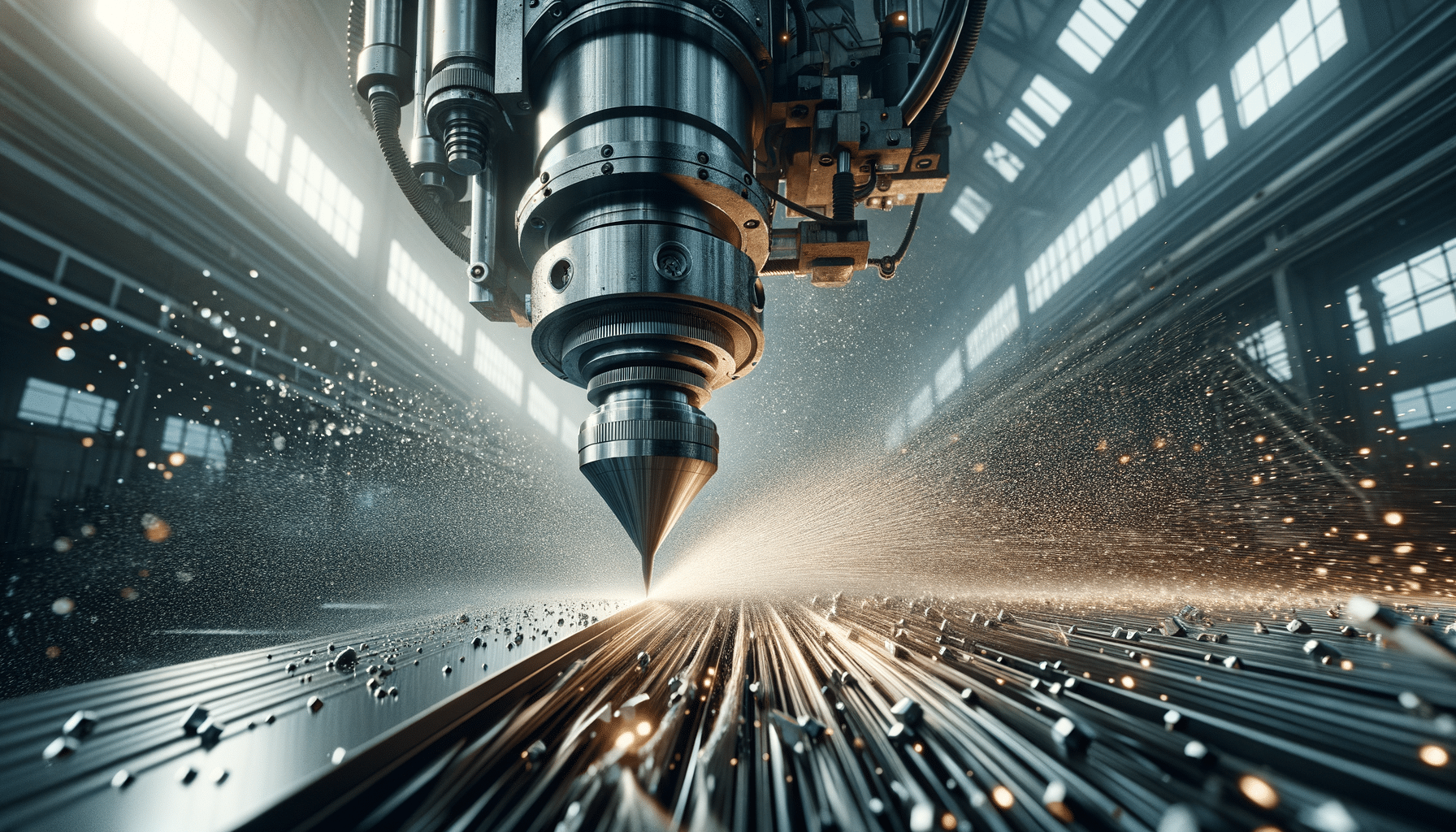

At the core of high pressure water jets is the science of fluid dynamics. These jets operate by forcing water through a small nozzle at extremely high pressures, often exceeding 20,000 psi (pounds per square inch). The resulting stream can cut through a wide range of materials, including metals, composites, and stone. The precision of the cut is determined by the pressure, the nozzle size, and the speed at which the material is fed into the jet.

Key components of a high pressure water jet system include the pump, which generates the pressure, and the nozzle, which focuses the water into a fine jet. The technology behind these systems has advanced significantly, allowing for greater control and efficiency. The ability to adjust the pressure and flow rate makes water jets suitable for delicate tasks as well as heavy-duty industrial applications.

Because water jets do not generate heat, they are particularly useful for cutting materials sensitive to temperature changes. This cold cutting process prevents thermal distortion and maintains the integrity of the material being processed. The science of water jets continues to evolve, with ongoing research focused on improving performance and expanding the range of materials that can be effectively cut.

Applications of High Pressure Water Jets

High pressure water jets are utilized across various industries due to their versatility and efficiency. In the aerospace sector, they are employed to cut complex shapes in advanced composites and metals without affecting the material properties. This precision is crucial for components that require exact specifications.

In the automotive industry, water jets are used for trimming and cutting parts, from body panels to interior components. The ability to automate the cutting process with CNC (Computer Numerical Control) technology enhances productivity and reduces waste. Additionally, water jets are used in the recycling industry to cut through materials like glass and rubber, aiding in the efficient processing of recyclable goods.

Beyond cutting, high pressure water jets are also used for cleaning purposes. They can remove coatings, clean surfaces, and even unclog pipes without the need for harsh chemicals, making them an environmentally friendly option. The adaptability of water jets means they are continually finding new applications, driven by innovation and the demands of modern industry.

Advantages and Challenges of Using High Pressure Water Jets

The advantages of high pressure water jets are numerous. They offer precise cutting capabilities without the need for secondary finishing processes, which saves time and reduces labor costs. The lack of heat generation is a significant benefit, as it eliminates the risk of thermal damage to the material.

Water jets are also environmentally friendly, as they use water as the primary cutting medium and do not produce hazardous waste. This makes them a preferred choice for companies looking to minimize their environmental footprint. Additionally, the technology can be adapted to cut a wide variety of materials, from soft textiles to hard metals, making it a flexible tool in manufacturing and construction.

However, there are challenges associated with high pressure water jets. The systems require significant energy to generate the necessary pressure, which can lead to high operational costs. Maintenance is another consideration, as the nozzles and pumps must be regularly inspected and replaced to ensure optimal performance. Despite these challenges, the benefits of water jets often outweigh the drawbacks, particularly in industries where precision and quality are paramount.

Future Trends and Developments in Water Jet Technology

The future of high pressure water jets is promising, with ongoing advancements aimed at improving efficiency and expanding capabilities. One area of development is the integration of intelligent systems that can monitor and adjust cutting parameters in real-time. This would enhance precision and reduce the likelihood of errors, further optimizing the cutting process.

Another trend is the miniaturization of water jet systems, making them more accessible for smaller businesses or applications where space is limited. Portable water jet systems are being developed for use in remote or challenging environments, broadening the scope of where this technology can be applied.

Research is also focused on reducing the environmental impact of water jets. Innovations in water recycling systems and the development of biodegradable abrasives are examples of efforts to make water jet technology more sustainable. As industries continue to demand more efficient and environmentally friendly solutions, the evolution of high pressure water jets will likely play a significant role in meeting these needs.